This is a paragraph! Here's how you make a link: .

When it comes to large-scale infrastructure like bridges and highways, project success hinges on material consistency, supply efficiency, and on-site adaptability. Contractors aren't just selecting equipment—they're mitigating delays, ensuring structural reliability, and managing costs down to the ton. Gravel crusher, in this context, has become the go-to machinery for a reason. These rugged machines aren't simply for breaking rock; they’re an essential part of material logistics, ensuring aggregates meet grading requirements and deadlines stay intact.

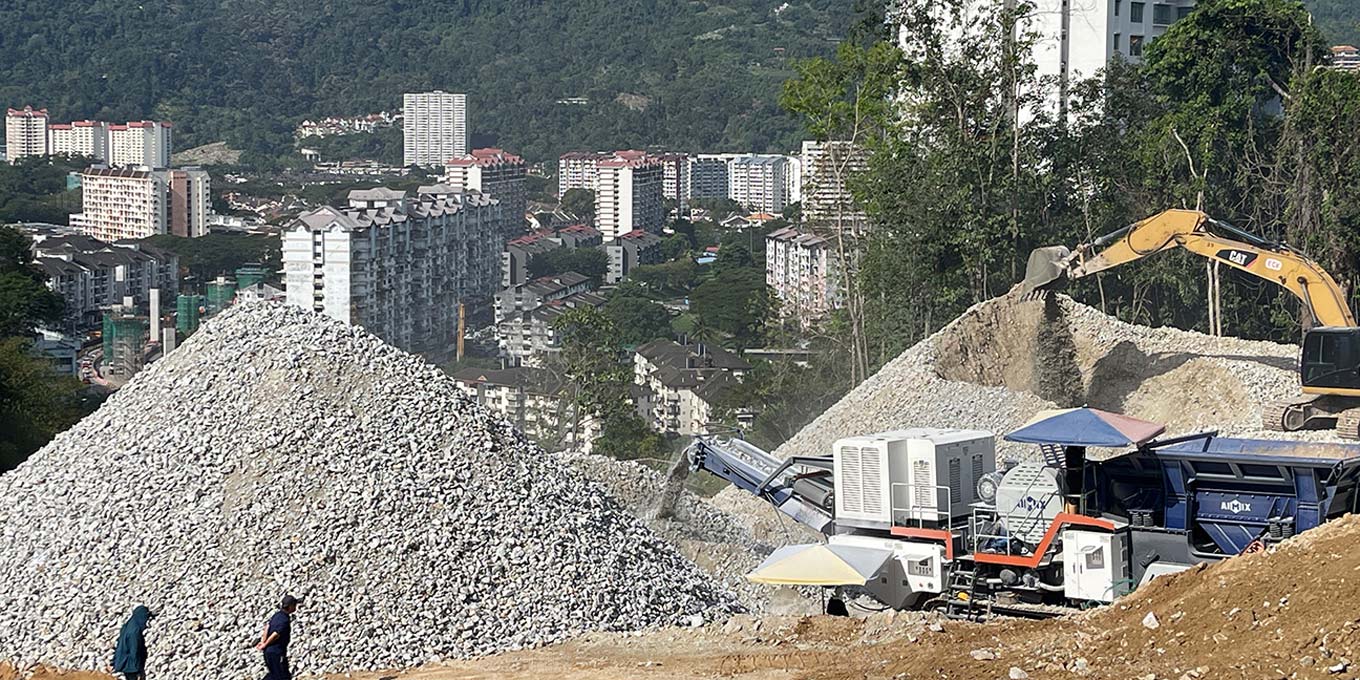

Whether you're crushing recycled concrete or native stone, gravel crushers deliver high-volume throughput, reduce transport dependency, and allow teams to work faster with fewer moving parts. With the increasing complexity of highway design standards and environmental regulations, it's not enough to rely on external aggregate supply chains. The ability to control your own production—directly at the job site—has changed the game for contractors. That’s why mobile and stationary gravel crushers are more than just equipment—they're strategic assets.

Bridge and highway foundations demand uniformity. Without consistent particle size distribution, compaction rates drop, load-bearing capabilities weaken, and pavement lifespans shorten. Gravel crushers enable contractors to process raw material into exact specifications—right down to the millimeter. From sub-base to base course, the ability to generate material on-site ensures that compaction testing doesn’t delay progress or require rework.

Most highway specifications outline strict gradation envelopes for different layers. Mobile gravel crushers, often paired with screening units, give project teams the freedom to crush, screen, and calibrate aggregates in real-time. That means fewer surprises during soil density tests and a higher likelihood of passing compaction standards on the first attempt.

Sourcing aggregates off-site introduces waste—both material and monetary. Trucking in aggregate from distant quarries leads to material loss during transport, scheduling headaches, and higher carbon emissions. On-site gravel crushing cuts these factors down dramatically. Contractors can recycle existing materials or crush native rock nearby, minimizing reliance on third-party quarries and reducing fuel overhead.

Additionally, projects benefit from reduced stockpiling needs. Processed gravel can be delivered straight to the laying area, shortening the time between excavation and final placement. This tightens production cycles and trims days off project timelines—an advantage when penalties loom for late delivery.

Modern gravel crushers come in mobile, semi-mobile, and stationary variants. For bridge and highway projects stretched across long corridors, mobile crushers offer a level of versatility that’s hard to beat. These machines can be relocated with minimal downtime, often following the progression of the construction corridor.

With crushing capacities reaching hundreds of tons per hour, mobile crushers don’t trade performance for portability. Their compact design and rapid deployment make them ideal for phased projects, where materials are needed at multiple sections simultaneously. A single mobile unit can replace dozens of truckloads per day.

Today’s gravel crushers are equipped with automation systems that monitor output size, engine load, and wear rates. Real-time adjustments keep product quality consistent and reduce unplanned shutdowns. Wear-resistant linings and high-torque drives also increase service intervals, translating into fewer maintenance stoppages and longer operational uptime.

This becomes especially important on federally funded infrastructure projects, where timelines are rigid and delays have a domino effect on subcontractors, permitting, and inspection schedules. Machines that optimize their own performance let crews focus on placing materials—not fixing machines.

Many bridge and highway projects are now held to environmental standards that require reduced emissions and material recycling. On-site gravel crushers help fulfill these mandates. By reprocessing demolition waste, old concrete, or rock excavations, contractors can produce certified aggregates with a lower environmental footprint.

In LEED-focused or green infrastructure projects, this approach can even be a differentiator in competitive bidding. It signals a commitment to sustainability while offering a practical edge in material logistics.

Controlling your own material production means controlling one of the biggest cost centers in civil construction. Aggregate crushers allow for more predictable pricing, fewer subcontractor dependencies, and built-in contingency planning. If supply chains tighten or prices spike, having in-house production capacity is no longer just a luxury—it’s risk management.

For bridge and highway contractors, the decision to invest in or rent gravel crushers is less about equipment and more about project command. In a climate where every delay is expensive, and every variable matters, gravel crushers offer something valuable: control.

To learn more HTML/CSS, check out these tutorials!